Industry organizations have developed widely accepted ergonomic guidelines for the set up of office workstations and the design of ergonomic chairs. What’s missing — and very much needed, I argue — is an objective methodology for making the decision to keep, repair or replace task chairs once they’re in the workplace.

Despite recent trends toward promoting more standing in the workplace, average sitting times now exceed 7.7-10 hours per day or longer in the workplace, not including commute time. Most employers do not yet have widespread capacity for sit-to-stand workstations. As a result, far more emphasis needs to be placed on selecting chairs and the ongoing use of an ergonomic chair.

The ergonomic chair life cycle (Figure 1) begins with conceptual design and materials used, includes the manufacturing process, the delivery and distribution, and workplace use, and ends with disposal.

There is sufficient information about the design of an ergonomic chair. Extensive research has enabled the Business and Institutional Furniture Manufacturers Association (BIFMA), American National Standards Institute (ANSI), and the Human Factors and Ergonomics Society (HFES) to identify guidelines for manufacturers, employers, and consumers around chair design.

Figure 1. Ergonomic chair life cycle with a focus on chair use, quality, and competency in the workplace.

However, there is a gap in the guidelines regarding how to assess the ongoing performance of an ergonomic chair after it enters the workplace. Evaluating the use of an ergonomic chair from a quality and competency standpoint is a critical part of the chair’s life cycle.

The question is how and when office chairs need to be replaced in the workplace. Currently, there is no formal methodology to objectively assess these key indicators.

Understanding the Risks

Once an ergonomic chair is purchased, it often remains in circulation far beyond its acceptable life cycle and warranty (three to 10 years, on average, depending on the manufacturer's warranty period). As a result, office workers continue to use chairs that are old, worn, outdated, and inoperable. These often inadequate chairs present additional ergonomic, product liability, and safety risk factors, such as musculoskeletal stress and strain, that can lead to injuries and workers’ compensation claims.

Incompetent chairs may lack support due to cushion failure, fabric degradation, poor frame design, sinking or failed cylinders, or inoperable mechanisms, including poor caster quality. These factors contribute significantly to chair dissatisfaction, sitting discomfort, and, ultimately, seated work injury claims. In a 2016 report, the California Commission on Health and Safety and Workers’ Compensation pegged the cost of such claims as Carpal Tunnel Syndrome and repetitive motion at $40,000 per (seated) work injury.

Popular office chairs are often recalled unbeknownst to employers. In one example in 2014, a major office supply store recalled a popular task chair, stating, “The mounting plate weld can break and separate the seat from the base of the chair, posing a fall hazard.” Of the more than 1.4 million of these task chairs that were sold, there were at least 153 reports of the seat plate weld cracking or breaking. The recall reported 25 cases of contusion, abrasions, and reports of injuries to the head and neck and a fractured back and hip, which required medical attention. Unfortunately, many unsuspecting employees use failing chairs like these. The price of the chair was $40, but the risk and liability were exponentially greater.

Conducting an Assessment

Employers can minimize the risk of ergonomic chair failures by evaluating them from the time of purchase to establish inventory before they are put out into the work area and a minimum of every three to five years thereafter, depending on warranty status. Routine assessments determine which chairs should remain in the workplace, be repaired or refurbished within the warranty period, or be replaced as a result of wear and tear.

The proposed methodology makes this a more objective decision by eliminating bias in chair replacement rather than relying on the subjective opinions of employees. Chairs are rated based on a value of poor as unacceptable, fair as acceptable, or good, with each rating possessing additional descriptive features to denote the lack of quality and competency of the chair.

The Chair Assessment Methodology assesses the use (quality and competency) of an ergonomic chair in six categories:

- Age of the chair

- Number of shifts used

- Chair cushion/fabric quality,

- Operational mechanics,

- Chair comfort (as perceived by end-user), and

- Overall quality and competency, taking all factors into consideration.

Establishing an Inventory

Assessing the ongoing use of an ergonomic chair does more than reduce the liability associated with seated work injuries and assures better comfort, quality, competency, and ultimately improved productivity by office workers. Evaluating for competency creates an inventory of chairs, which ultimately shows which chairs are performing well over time, offer the best fit, have a high degree of end-user comfort to remain in operation for safe and productive work, and whether they are worth keeping as part of the organization’s standard chair inventory.

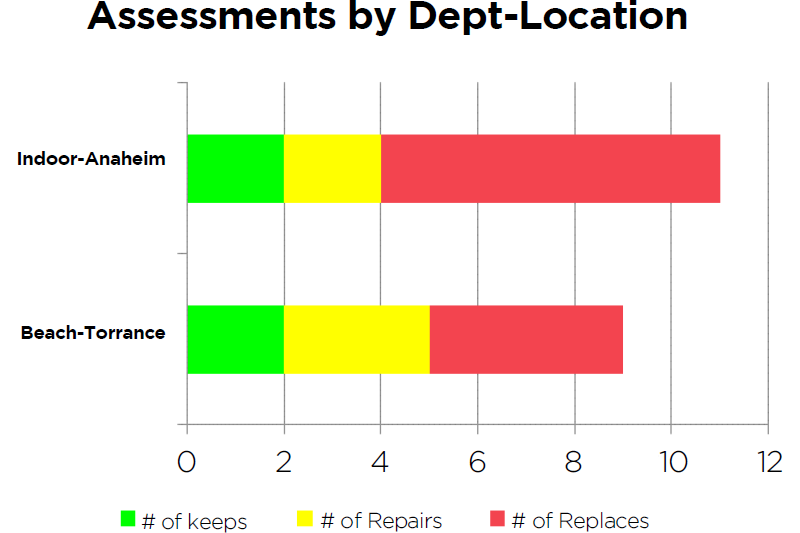

Figure 2 shows an example, by department, of which chairs should remain (green), need repair (yellow), or should be removed from circulation and replaced (red). Once a chair is removed, the selection and fit process can begin.

Figure 2. Using the Worksite International Chair Assessment System, employers can track which chairs to keep, repair or replace by department following a quick assessment of the chair.

The inventory also allows the organization to prioritize which chairs should be repaired or replaced based on an objective assessment of the age of the chair, fabric/cushion quality, operational mechanics, end-user comfort, and overall value. This, in turn, allows facility and purchasing managers to anticipate the budget necessary to repair, refurbish, or replace the selected chairs over time.

Replacing broken, failing, and worn-out ergonomic chairs in a timely manner is an important part of their life cycle and a critical component of the ergonomics program that aims to prevent and manage seated work injuries more effectively.

When employers objectively assess ergonomic chairs for quality and competency, organizations can save thousands of dollars in risk management, claim avoidance, and productivity improvement by keeping employees safe and comfortable throughout the seated workday.

Chair Predictive Analytics

To learn more about our unique and novel ergonomic chair assessment tools, visit our website and request a demo. Our chair asset management software is ideal for facilities and purchasing managers or ergonomic program managers, or in-house ergonomic evaluators who are looking for predictive analytics to track chairs in real time.

Using asset management software will decrease administrative time, improve service maintenance, save money through the use of warranty, and identify chairs truly worth investing in for the long term.

In addition, our online Chair Assessment and Chair Fit training will help you improve your chair asset management skills by learning how to perform chair assessment, selection, and fit. Training includes the full complement of Chair Assessment and Fit System tools.

References:

1. 2003-04 National Health and Nutrition Examination Survey (NHANES) study.

2. The Canadian Health Measures Survey, Colley et al., 2011

3. California Commission on Health and Safety and Workers' Compensation 2016 Annual Report

Comments (3)